Other Rolling Mill Equipments

- Plate Bending Machine / Plate Rolling Machine

Plate bending machine is used for bending the plates in round shape in the cold form. We manufacture Mechanical and hydraulic plate bending machine for MS Plates.

The current maximum capacity machine is of upto 32mm with 3000mm width.

- Charging Pusher

A charging Pusher is an Electro-Mechanical or Hydraulic device which is used for feeding or charging of raw material (like ingots, billets etc) into the reheating furnace.

Various components which are used in the manufacturing of a Charging pusher are : Heavy steel slab frame pushing screw with pushing slab, multi stage type reduction gear box or a hydraulic power back with alloy steel shafts in case of a hydraulic pusher.

Depending on the raw material to be feed i.e. scrap/miss roll, ingots/billets or heavy blooms and their sizes, the mechanical or hydraulic type pusher is designed and supplied.

- Discharging Ejector

Discharging Ejector is an Electro-Mechanical device which is used to expel the hot material from the reheating furnace to the Rolling Mill. It has a mill housing type structure with a movable frame and can do both front and side travel for discharging of Hot Material (like ingots, Billets) from re-heating furnace.

It comes complete with heavy stands, rollers, cooling systems, wheels for cross travel, gear box and pushing arrangements etc. it uses a square billet of approx. 6 meter (or more) length as the device to push the hot material out of the re-heating furnace.

It is manufactured depending on the size and capacity of the re-heating furnace.

- Billet Grabber / Pallet Grabber

Billet Grabber is a mechanical device used in Steel Melting Shops for grabbing the Ingots/Billets. It helps in properly placing the finished goods in stock yard. It is very safe to used has very effective results

It is not a magnetic, hydraulic, electronic or pneumatic device. It is a pure mechanical device and has a number of advantages over other material lifting equipments with a fully reliable and a total mechanical interlocking system it can help save a lot of time and resources and hence result in the increased productivity by many folds.

It comes in various sizes and capacities.

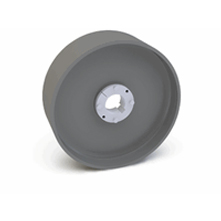

- Pulley

A Pulley is a power transmission cum speed controller device which can be used at various places depending on the application and size.

In Rolling Mills it is used between motor to flywheel and flywheel to gear box so as to control speed input speed as per the application and size.

In Rolling mills it is used between motor to flywheel and flywheel to gear box so as to control speed input speed as per the application. It is duly machined and balanced and comes in all groove sizes and bores. The material mostly used to manufacture the pulley is Graded Cast Iron. We make pulleys from 150mm to 3500mm dia.

It comes complete with shaft, bearings, Plummer Blocks, Base Plates and Foundation Bolts etc and is designed and manufactured as per the application.

- Repeaters / Loopers

Repeaters or loppers as usually called, is a mechanical device used to repeat the hot bar in the same stand or the adjoining stand. Basically they are used for transferring the Bars/Re-Bars/Deformed Bars/TMT Bars from one stand to another. These help in saving labor and increase the production as the material is automatically shifted from one stand to another.

Repeaters are fabricated out of MS plate and it consists of Nozzle, Jack Adjustment Base and Foundation Rails.\ The repeaters are designed and manufactured as per the requirement of the application. We also manufacture escapement type repeaters and special repeaters with inbult pneumatic type snap shears.

- Gear Couplings

A Gear Coupling is used for transmitting torque and power between two shafts it is normally used for the coupling of Motor to fly wheel, fly wheel to gear box etc individually designed and manufactured to specific requirements.

- Nylon Sleeve Coupling

The nylon sleeve gear coupling is a compact & lightweight coupling that uses nylon sleeves as a device for shaft coupling & torque transferring Lubrication is not required with the nylon sleeve and they are highly effective for high RPM, the nylon sleeve gear couplings are effectively used in applications such as motor/generator sets, motor/pumps sets, and many other industrial settings.

- Universal Couplings

Universal Couplings are inserted at the journal of the rolls, to couple the mill stands. These are basically for the power transmission from one stand to another.

Manufactured out of forged steel, they are highly applicable at mill stands with repeaters or high loads.

They are designed and manufactured as per the load of the application

- Cardan Shaft

Cardan shaft was invented in 16th century by GirolamoCardano, It is a mechanical component for transmitting torque and rotation, usually used to connect other components of a drive train that connot be connected directly because of distance or the need to allow for relative movement between them. It can also accommodate a varying shaft angel.

Application : Hot Rolling Mill, Cold Rolling Mill, Tube Mill, Textile Mill, Paper Mill Cement Industries, Mining Industries, Auto Sector, Agriculture Industry Etc.

- Roller Guide Boxes & Twiest Pipes

Twist Pipe & Roller guide box are installed at the entry and exit of the Mill Stand in Rolling Mill. They are used for guiding of symmetrical section such as Round Oval Square, Flat etc into Mill Stand s for Rolling.

These are Stainless Steel Casted pipe and boxes which consist of precisely machined Body, Leaf, Set of Guides, Nuts & Bolts and Pins & Roller Bearing. The water system for cooling the rolls of the guides is effectively designed and precisely machined in-order to get maximum cooling for the high Alloy Rolls.

We manufacture all standard and custom size Twist Pipes & Roller Guide Boxes such as- Morgadshammer Type and open leaf type

- Roller Conveyors

One of the Mechanical Material Handing equipment provided by us is the Roller conveyor/table which are used for the transfer of hot / cold material from one station to another.

These are steel fabricated structures and consist of fully machined Seamless pipe/barrel, Alloy Steel Round, Steel Structure, Chain Sprockets, V-belt pulley, Bearings & Bearing blocks complete with lubrication system. They are driven by Geared Motor or gear boxes and motor with chain and chain sprockets or motor and pulley with v-belts as per the requirement and suitability.

We manufacture all standard and custom size conveyors and roller tables such as :- Mechanical and Hydraulic-Y Table, Lifting Table, Transfer Table, Run Out Table etc.

- Universal Spindles

Spindles are used a device for power transmission and are place between Couplings.

Spindles are manufactured out of forged steel, basically EN-8 OR EN-9 and are properly machined as per the design and requirement.

Our manufacturing range of spindles includes :- Palm /Key Groove Type, Star Groove Type

- Oil Lubrication System

Oil Lubrication systems are used t maintain regular supply of ambience temperate oil mating part of Gear Boxes in Rolling Mill.

Oil Lubrication Unit is a Pit Hole type box, fabricated out of M.S. Plate body and comes complete with all the accessories like : Oil Reservoir, Heat Exchanger, Oil Strainer, Contact Thermometer / Manometer, Duplex Filter, Pressure Gauge, Pipeline to & from the Gear Boxes, Complete with the Control Panel.

The system so designed that the lubricant flows back to the reservoir under the influence of gravity. We manufacture all standard and custom size oil lubrication systems based on the LPM etc.

- Bearing Chocks

These Bearing Chocks are rolling mill duty will be installed in between window of rolling mill stand. These Bearing Chocks are suitable for anti friction roller bearing. The bearing chocks are of EN – 8 with Fully Machined accurately the bearing sizes. The bearing chocks are complete with side cover, sleeves / Lumbering & chick nut.

- Disc Type Hi-speed Flywheel

Salient Features :- Dynamically & statically balanced.

- Ultra sound testing processed for detecting any cracks.

- Suitable for High speed rolling mill.

- Forged Steel EN-8 fully machined Shaft.

- Heavy Duty Plumber blocks.

- Spherical roller bearings.

- Reduction Gear Boxes & Pinion Stands

The Gear Boxes (Reducers\Increasers) & Pinion Stands designing & manufacturing is also frame of our technical and engineering expertise with modern features as per industrial standard and requirements. The Gears will forged & hardened cased in sturdy steel fabricated body to bear shocked overload of mill. The Pinion gear boxes & Gear boxes are mainly rolling mill duty.